Boatshed Phuket: What's with New Sails?

With the continuing advances in sail technology, yacht owners are inundated with information on the vast array of materials available when wanting to order new sails.

The aim of this article is to provide information, in a relatively simple fashion, regarding what is available and to assist owners selecting the most appropriate materials for their sails.

I’m writing this from the perspective of what most companies in the market have available. While terms vary a bit, as do the products; the general characteristics are fairly similar.

These days almost all sail design is done with computer programs. The panels or layout of the sails are prepared by machines that enable accuracy with a minimum of costly labour.

This design and production process also enables proven sails to be replicated very accurately.

Design is critical and, in my opinion, care should be undertaken to ensure the sails fit the rig, and characteristics, of each individual yacht. As an owner, you really should have a sail-maker who is prepared to look at things from your perspective and recommend only construction methods and materials they think are appropriate.

All sails should be designed to be “fast” and the materials and construction methods used to the tailored to individual owner’s use requirements and to be as cost efficient as possible.

While racing sails are designed and constructed for optimum performance, Cruising/Recreational sails are built for longevity but should still be powerful.

The reality is that most boats fall between the extremes above so the selection of sail type depends on prioritising the characteristics required.

Mainsail and Headsail construction methods fall under three main types; Cross-Cut Panel, Radial Panel and Membrane Laminates.

Cross Cut sails are produce from a variety of various products of Dacron and Laminates.

Cruising Dacron is designed for maximum and durability, for use in cruising/recreational applications. These materials do not use heavy resin coating so are easily stowed. These materials are usually economical and long wearing.

High Performance Dacron is more performance oriented and is tightly woven. It usually comes in High Aspect and Low Aspect styles. High Aspect is for use in mainsails and high aspect headsails. Low Aspect is an all purpose balanced cloth suitable for many applications.

Premium Performance Dacron is ideal for racing or cruising. It is very tightly woven resulting in less sail-shape deformation and long life. With the strength and durability, we have found that Premium Performance type has proven excellent for yachts with heavy use.

One Design Dacron is made for racing classes up to and including J24’s, E22’s and Dragons. It precisely manufactured and tested at predetermined positions throughout, to standards well in excess of other sailcloth.

Storm Dacron is heavy Bright Orange cloth for Trysails and Storm Jibs, and complies with the safety requirement for high visibility Storm Sails.

Multi-Film Cruising Laminate utilises two films and is laminated as a membrane featuring tear strength and impact resistance. It has a Taffeta exterior cover and generally laminated with an Anti Fungicide for the prevention of mildew and mould growth that can occur with this type of Sailcloth.

Axis Cruising Laminate is for high quality, durable performance cruising sails. The sails have a membrane design using cross-cut panels parallel to the foot. Computer analyzed load lines are determined then Pentex or Vectran fibres are strung across the sail panel with density varied with load. These sails have 100% UV block film.

Both the Laminates above have Polyester Taffeta laminated to both sides with an ant fungicide additive for mildew and mold protection, and are suitable for cruising applications up to 45 feet.

Most Radial Panel Sails are used for racing applications although laminates are now available for radial cruising sails.

It is important with these to match the laminate characteristics to the relative rigidity of your boat and rig.

Cruising Laminate is Film-on-Film Polyester with an internal Taffeta core which provides a lighter alternative to Multi-Film laminate. It is suitable for use on racer/cruisers up to 45ft.

Pentex Laminate is ideal for small keelboat and sport boats for applications that demand more strength than standard Polyester and one-design classes where high modulus fibres are not allowed. The range of this laminate has increased so it’s now has suitable applications on larger yachts.

Aramid Laminate is ideal for racing applications up to 55 feet. Construction provides low stretch, light weight and cost effectiveness.

Dinghy Laminates are designed to be used for a variety of one design and small keelboat applications, ideally suited for radial construction of sails. It exhibits good durability and performance, providing a rugged construction and a modern hi-tech appearance.

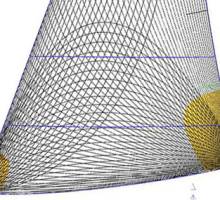

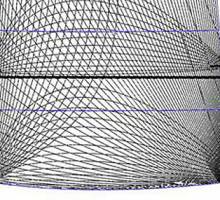

Membrane sails have evolved with improved stringing and laminating techniques. On the water this results in light, strong and fast sails.

These “High end” custom membrane sails are available both for cruising or racing.

Again the range of construction styles, finishes and fibres used are comprehensive.

Film/Film sails are constructed for racing for modern skiffs up to the maxi racers. The choice of fibres enables you to get the qualities you require and, in most cases, your own look. Film thickness varies depending on sail size.

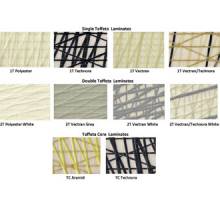

Single Taffeta has a Film surface on one side and Taffeta on the other, and is a good choice for the racer/cruiser. The Taffeta adds durability and longevity while maintaining a hi-tech look.

Double Taffeta has Taffeta on both sides of the sail and is the ultimate cruising product as the sail is light, strong and protected by the rugged taffeta exterior.

Taffeta Core has a taffeta sandwiched between the external film and fibre layers. This gives increased durability over typical film/film only sails.

Common fibres in membrane laminates are:

Polyester Vectran Carbon / Technora

Pentex Technora / Aramid Carbon / Vectran

Aramid (Gold) Vectran / Technora Carbon

Technora (Black) Carbon / Aramid

Downwind Sails include Symmetric and Asymmetric Spinnakers and furling Asymmetric Spinnakers and Gennakers/Code 0’s.

Now a form of radial design is the norm, in a very wide range of Materials, the most common I will mention here.

Below is a table of the most commonly used types of Spinnakers with target apparent wind angles (AWA).

Target Wind speeds often dictate the requirement for sails of similar target apparent wind angles but constructed of materials of varying strengths or characteristics.

Symmetric Spinnakers Asymmetric Spinnakers

Name Target AWA Name Target AWA

VMG Sym 55º-110º Code 0 AWA 40º -90º

Reaching Sym 75º-120º Gennaker AWA 55º -110º

Downwind Sym 110º-180º Reaching Asym AWA 70º -120º

All-Round Asym AWA 90º-150º

Downwind Asym AWA 115º-165º

The modern nylon used in Spinnakers has been improved and is suitable for most Cruising, Recreational and Club Racing applications.

The High Tenacity Nylon we use now exceeds strength normally used for generic Cruising Nylon and incorporates a 5 mm ripstop is woven into the material.

Weights of Nylon used are 0.75,1.5 and 2.2 oz.

AIRX Spinnaker Cloth has set standards combining strength, performance and quality This fabric allows Grand Prix sailors to use lighter sails higher up the wind range and club racers to use lightweight sails that are far less likely to blow out or tear and cover a greater range of wind speeds. AIRX fabrics provide spinnakers with lighter weight, stability, strength water resistance and durability.

AIRX-500 has almost meant the end of generic 0.5oz spinnakers. It now features ripstop construction, providing even higher tear and burst strength, despite being one of the lightest cloths available.

AIRX-600 is ideal for medium wind range spinnakers despite being classed as a generic 0.5oz providing 0.5oz performance in reaching spinnakers and running sails capable of withstanding unprecedented wind strengths

AIRX-620S has silicone is added to the finish of AIRX-600 resulting in a high slip spinnaker fabric. The Silicone maximizes water repellency and reduces surface friction, making for easier gybing of asymmetrics, hoists and drops from spinnaker bags and chutes.

AIRX-700 is a generic 0.75oz product that suits Grand Prix racers looking for ultimate performance to cruising sailors expecting durability.

AIRX-900 is a high performance cloth designed to be used in composite constructions with AIRX-700 or for heavy reaching and runner spinnakers on yachts over 45ft.

Code Zero is an ultra-flat asymmetric spinnaker. They are increasingly popular on the racing circuit. and work particular well for fractional rigged yachts with non-overlapping jibs, acting as a large Genoa type sail to get VMG in light airs and to give extra horsepower when reaching.

Code Zero’s for IRC boats have to be designed with Spinnaker Mid Width (SMW) greater than 75% in order to be rated as a spinnaker.

Gennakers are designed with a smaller mid width than that of a racing boat and is a real performance aid for Cruising, and Racing Yachts not restricted by rating rules.

In many instances for these sails, conventional spinnaker fabrics have insufficient stretch resistance to provide a stable foil shape so a specific Code 0 laminates or Membrane sails are required.

Should any reader require more information, Rob Williams can be contacted at info@seair-sails.com

"first published in SEA Yachting"

Related Links: